Archive

Mendel in the Cambrian

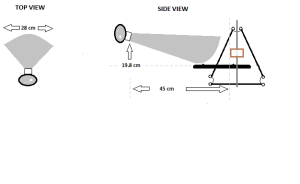

So, after weeks of building non-functional extruders, I decided to turn my attention to other things that I have left on the backburner for far too long. Herewith, is a short description of a computer-vision application, specifically written to monitor mendel movements. I have included a video, of my findings…. but firstly, the video does require some explanation.

This video is the output of a C++ application, that tracks mendel motion, as that motion relates to instructions, received from reprap host software, and consequently executed by the mendel hardware. The application generates a clear, visual comparison between true- and target positions.

A little bit of printing….but not too much

So, I have a mendel that prints little bits at a time. And the main culprit, barring me from full functionality at this time, is definitely the extruder. I have mastered such esoterica as; axis belt tensioning, homing, axis squaring, printbed preparation, extruder preparation etc.

At the present, my printbed is not heated. To compensate for this, I have temporarly put double sided tape on the print surface. I will experiment with Kapton tape at a later date, once I have optimised my extruder settings, and built the electrnics for the heated bed.

I am experimenting with different extrusion temperatures, and tentatively settled on 230C. This is the temperature as reported by the RepRap Host software, and I have no idea how close this reported value is to the “actual”/true temperature value. The extrusion rate is glacial. Even when applying a considerable amount of manual force, i.e. bypassing the motor all-together. And I am left wondering which of the following might be the reason for my slow extrusion:

- There is some adhesion chemistry going on inside the hot-end

- My extruder motor needs to be more “burly” i.e. requires more torque

- There is something peculiar about the chemical make-up of my particular batch of ABS

There is another peculiarity of my current mendel setup: my heater stops working at random times. I am not sure whether this is due to some software configuration issues like firmware/RepRap host software compatibility, or maybe something completely different. Loose electrical connections could also cause erratic temperature readings, but I have located and fixed all loose connections….I hope.

Below are some sample pictures of the Mendel geared extruder.

And another view….

The blue tape, is a little bit of insulation wrapped around the melting zone, which includes the kapton tape insulated nichrome wire, and thermocouple sensor. The PTFE thermal barrier was inserted into lasercut portion with epoxy.

The printbed has been covered with double-sided tape, as a temporary measure, until I get the extruder configured correctly.